baddoggoodlife

Member

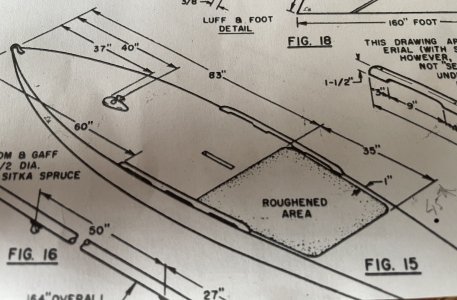

Hello all. Long term stalker, first time posting. I’ve had the privilege of restoring an exceptional example of a very early Super Sailfish. I’ve gotten to know her well, and feel like I’ve also learned much about her sole owner, and even her builders through the process. I’m only midway through the process, but felt this was a good time to reach out for more information from the collective knowledge base. Many thanks to the folks who have shared their wealth of expertise. I hope this particular boat helps to add to the preservation of these boats history.

Attached are a couple of pictures of how she came to me.

Attached are a couple of pictures of how she came to me.