mitka

Member

Hi Folks,

This past weekend I bought a Sunfish from a private owner in Alabama. The boat was his dads.He mentioned not knowing much about the boat, but it seems he new enough to lie about the year (this thing is NOT 1974, hah).

I am now the proud owner of a 1971-1972 Sunfish with the classic rudder bracket, cockpit-hull split and all. The rudder board is split at the top, and has a chunk missing. It would require some serious R&R to make structurally sound.

The Sunfish will be my daughter's first boat. She wants to skipper catamarans when she's older. I priced our the rudder conversion kit. Seems like a better option than replacing the rudder board. BUT, I'm not sure what to do about the design flaw in the cockpit, where the hull splits away from the bouncing around when towing.

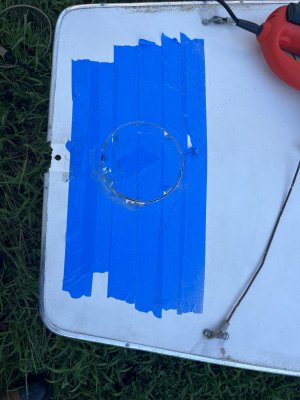

I'll have an access hole in the back after the rudder replacement, so draining any water in the hull will be manageable after an outing. The previous owner did an amateur's job of sealing the fissure up, but it's old and I should probably redo that at the least. Shall I flip the thing, sand it down inside the cockpit, and add a fiberglass flange to rejoin them?

Regards,

Kris

This past weekend I bought a Sunfish from a private owner in Alabama. The boat was his dads.He mentioned not knowing much about the boat, but it seems he new enough to lie about the year (this thing is NOT 1974, hah).

I am now the proud owner of a 1971-1972 Sunfish with the classic rudder bracket, cockpit-hull split and all. The rudder board is split at the top, and has a chunk missing. It would require some serious R&R to make structurally sound.

The Sunfish will be my daughter's first boat. She wants to skipper catamarans when she's older. I priced our the rudder conversion kit. Seems like a better option than replacing the rudder board. BUT, I'm not sure what to do about the design flaw in the cockpit, where the hull splits away from the bouncing around when towing.

I'll have an access hole in the back after the rudder replacement, so draining any water in the hull will be manageable after an outing. The previous owner did an amateur's job of sealing the fissure up, but it's old and I should probably redo that at the least. Shall I flip the thing, sand it down inside the cockpit, and add a fiberglass flange to rejoin them?

Regards,

Kris